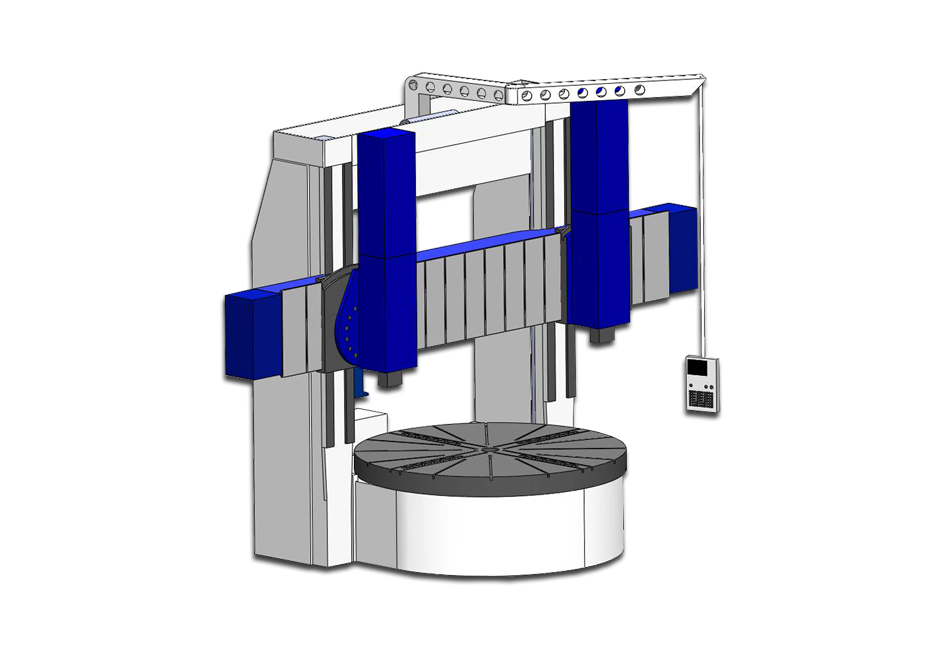

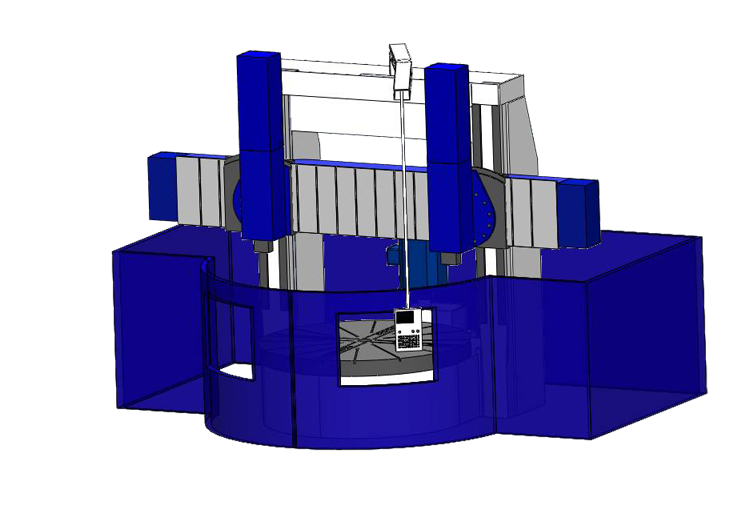

The vertical lathe with numeric control system is suitable for manual and NC machining operations with constant cycles.

The double column vertical turning lathe is used for machining different workpieces from ferrous and nonferrous metals in small and large scale productions.

Powerful electric motors and a very robust design allows fast and accurate processing.

The machine can perform following works:

• circular cone turning of outer and inner surfaces

• facing with constant cutting speed

• turning of grooves

• tapping, drilling, sountersinking and reaming

Design: cast machine frame, rigid construction

Operation: by hanging desk, feeds with four-way switch

Supports: The machine is equipped with two vertical supports for holding triple steel fasteners

Gears: chrome steel, hardened and ground

Couplings. Electromagnetic clutches for shifting the speeds and feed movements.

Clamp:. Crossbar / supports electro-mechanical

Faceplate Storage: 2x stored in adjustable radial cylindrical roller bearings

Lubrication: faceplate, guideways, gears by independent central lubrication

Control:

Simple programming procedures allows operating without sophisticated CNC programming /operation skills. The machine-/ control concept is optimally prepared to meet all current high-precision rotating productions, despite the very simple machine operation.

NC programmable controller with touch screen function

• direct programming in manual mode of single part production with input of spindle speed, feed and position in the digital display

• programming of predefined standard machining cycles

(24 treatment cycles) in a single sentences as well as in the automatic block sequence

(to 25 cycles in a program)

• teach cycle

• input of tool parameter

• internal program memory (up to 5 edited programs) and external (compact flash)

• Fault diagnosis and display

| Title | Unit of measurement | Data |

|---|---|---|

| faceplate Ø | mm | 8000 |

| machining Ø | mm | 8000 |

| height of workpiece | mm | 3200 |

| weight of workpiece | kg | 125000 |

| max. torque | kNm | 392 |

| speed range | r/min | 0-19 |

| steps of main drive | 4 | |

| performance of main drive | kW | 125 |

| cutting force of the right support | kN | 100 |

| cutting force of the left support | kN | 80 |

| range of vertical and cross feeds | mm/r | 0-300 |

| max. stroke of the crossbar supports | mm | 2000 |

| machine dimensions: | ||

| lenght | mm | 8600 |

| width | mm | 17600 |

| height | mm | 9800 |

| weight | kg | 248000 |

Schreibe einen Kommentar